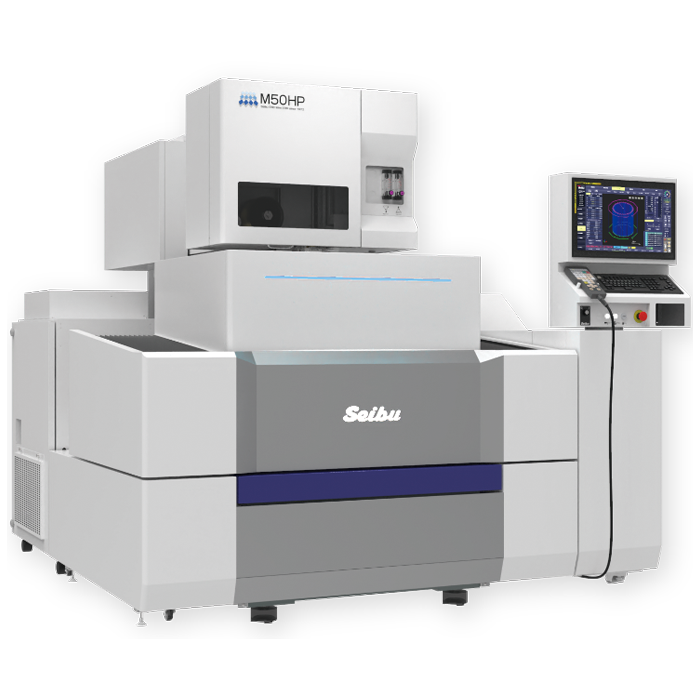

The M50HP Seibu Wire EDM machine delivers high accuracy and reliable performance for shops that demand precision. Designed for tight tolerances and optimal surface finishes, this CNC wire EDM system is suitable for a wide range of materials. With its rigid frame and stable construction, the M50HP consistently performs in demanding production environments, such as aerospace, tool and die, and medical manufacturing.

Seibu’s patented automatic wire threading system gives the M50HP a major edge. The machine straightens and anneals the wire before threading, allowing it to pass through narrow start holes with ease. If the wire breaks during a job, the system rethreads it automatically at the break point. This feature reduces downtime, supports unattended operation, and increases output in wire EDM machining.

The Smart NC control simplifies every job. It includes a library of cutting conditions and a user-friendly interface. Operators can set up parts quickly and trust the machine to maintain accuracy throughout the process. The system automatically adjusts cutting parameters, ensuring smooth operation even during extended periods of use. With its fast setup and minimal interruptions, the M50HP CNC wire EDM system enables manufacturers to boost productivity without compromising quality. From complex part geometries to high-volume jobs, the M50HP offers a complete solution. It combines proven Japanese engineering with smart automation to meet the needs of today’s precision manufacturing. If your shop requires consistent results, reduced labor, and lights-out capability, the M50HP Seibu Wire EDM machine delivers on all fronts.