Description

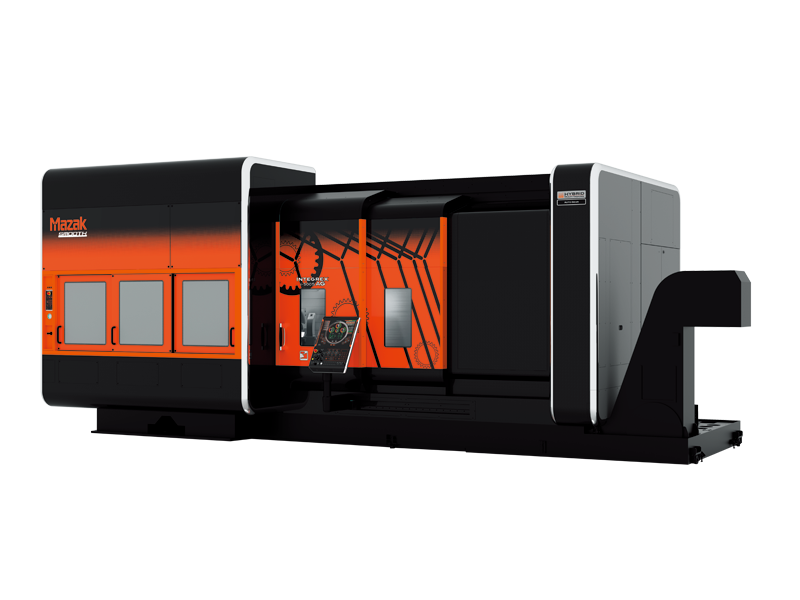

INTEGREX i-5005ST AG Dual-Spindle and Lower Turret

This 5-axis machine’s configuration introduces a second turning spindle (S) and a lower turret (T), to minimize fixtures, tools, handling, and non-cut time. In addition, this machine also features a HYBRID AUTO GEAR package alongside a full range of SMOOTH TECHNOLOGY solutions. This DONE IN ONE® gear production surpasses conventional capabilities to maximize productivity in the CNC machine shop. The Mazak INTEGREX i-5005ST AG is a highly precise and versatile 5-axis machine to efficiently handle fully prismatic parts from solid blocks to castings. For example, it machines round or complex aerospace components, whether they are chucked or bar-fed with ease and accuracy.

Rigidity and Accuracy: The Foundation of High-Performance Machining

The standard 50-taper spindle provides essential rigidity for high-precision machining. When combined with process integration, this feature significantly reduces in-process time and initial cost. In addition, operators can effortlessly set and adjust the tailstock position via the setup screen. This facilitates the efficient transition to different machining operations without compromising precision or productivity.

Leading the Way in Complex Fabrication and Aerospace Engineering

The Mazak INTEGREX AG Series, particularly the i-5005ST AG model, enhances production line flexibility and delivers maximum versatility. With powerful turning spindles and advanced control features, it offers heavy-duty performance tailored for the most demanding tasks in aerospace, automotive, and contract manufacturing industries.

Compare to other Mazak 5-Axis machines for sale