Description

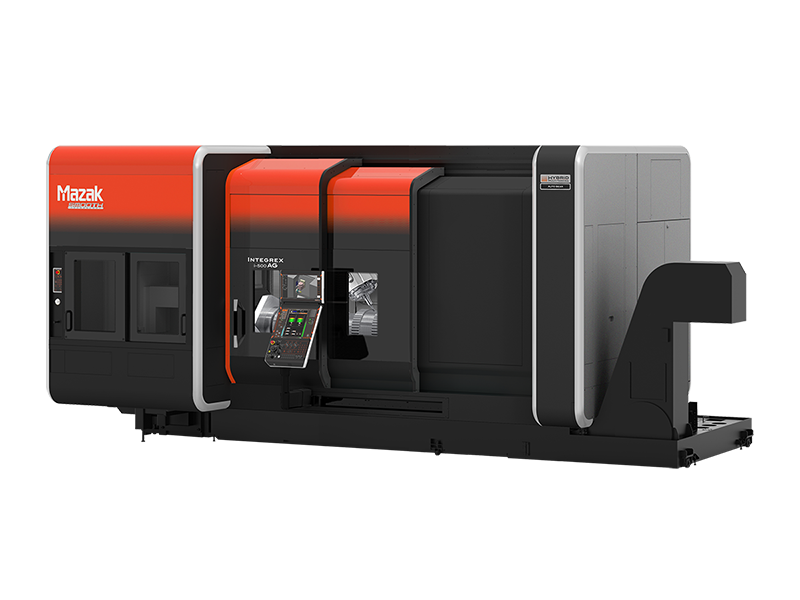

Streamlined Production with Advanced Technology on the INTEGREX i-500ST AG

This 5-axis machining center embodies a DONE IN ONE® machining philosophy with a second turning spindle (S) and lower turret (T). This strategic configuration minimizes the necessity for excessive fixtures, tools, and manual handling, significantly reducing non-cut time. In addition, the comprehensive suite of SMOOTH TECHNOLOGY solutions, including the HYBRID AUTO GEAR (AG) package elevates gear production to unprecedented levels of precision and speed.

Unmatched 5-Axis Capability for Diverse Applications

This machine’s 5-axis capabilities reduce lead times while accurately processing materials, whether they are chucked or bar-fed, round or sculptured. For example, it can machine from solid blocks or castings to intricately sculpted aerospace components. In addition, the process integration techniques reduce in process times, and initial set up costs for efficient manufacturing. The INTEGREX i-500ST AG HYBRID also quickly and easily generate programs for cutting tool paths and measurements. As a result, it provides a seamless workflow for machine operators.

Innovative Features for Superior Performance

The INTEGREX i-500ST AG SMOOTH Gear Cutting software package includes Gear Skiving, Gear Hobbing, and Gear Milling to produce external and internal gears. For example, it machines spur, helical, and spline-type, with unmatched accuracy. It also has an MX Hybrid Roller Guide System to effectively dampen vibration, extend tool life and facilitate higher load capacities. This advanced technology ensures that machine shops can tackle challenging projects, reduce downtime, and maintain high-quality output. As a result, they can make a substantial leap forward in operational efficiency and their industrial competitive edge.

Compare to other Mazak Multi-Tasking machines for sale