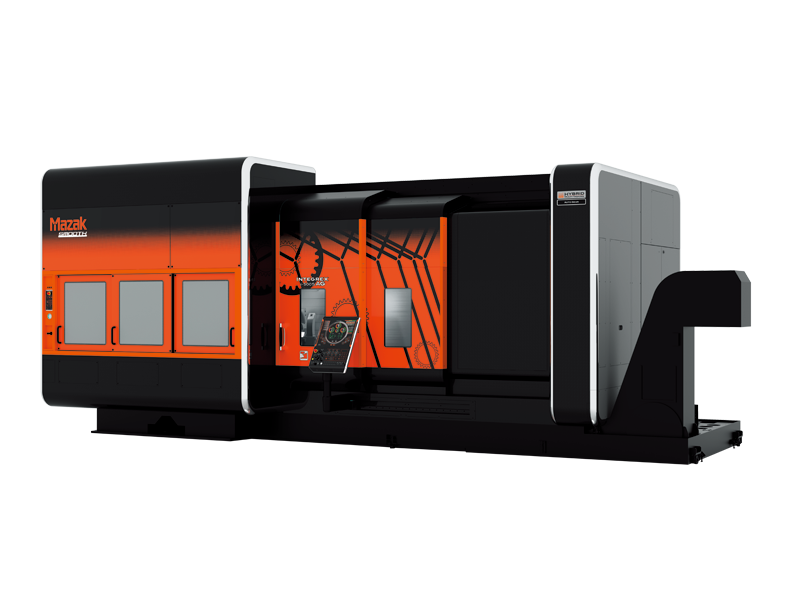

Description

Innovative INTEGREX i-5005 AG HYBRID AUTO GEAR (AG) Technology

This machine is at the forefront of manufacturing innovation, thanks to its HYBRID AUTO GEAR (AG) package. This cutting-edge feature integrates a suite of SMOOTH TECHNOLOGY solutions to revolutionize the way gear production is approached. This machine’s technology package allows for consistent, precise, and efficient gear machining processes. For example, it can complete hobbing, skiving, and milling projects for automotive and aerospace industries. These advanced capabilities streamline the manufacturing workflow to produce complex gears in a single setup. As a result, production times, and setup errors are significantly decreased for DONE IN ONE® gear production.

Enhanced Productivity and Precision

The INTEGREX i-5005 AG HYBRID 5-axis capability is a game-changer. It allows efficient and precise processing on fully prismatic parts from a diverse range of materials. For example, it machines solid blocks, castings (either chucked or bar fed), round components, or complex sculptured parts like those found in aerospace applications with ease in a single setup. This convenient feature speeds up production, and ensures that each piece meets accuracy and quality standards for industries requiring intricate designs and tight tolerances, such as aerospace, medical, and precision engineering. By reducing in-process time and lowering initial costs, the INTEGREX i-5005 AG HYBRID is a standout solution in Mazak’s lineup of 5-Axis integrated machining solutions. In conclusion, this machine caters to the demands of high-precision engineering, embodying Mazak’s commitment to innovation, quality, and efficiency.

Compare to other Mazak 5-Axis machines for sale