Description

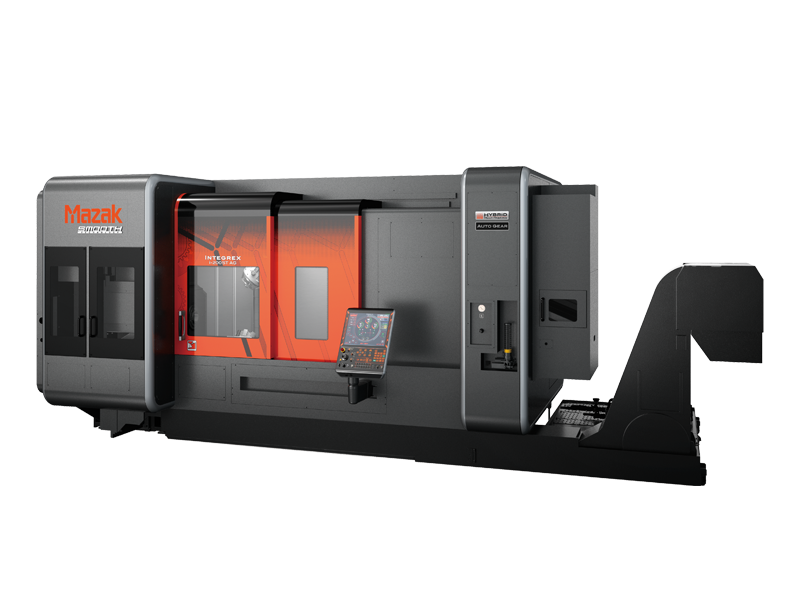

INTEGREX i-200ST AG was Designed for Comprehensive Machining

This 5-axis machining center features a second turning spindle (S) and a lower turret (T) to minimize fixtures, tools, and excessive handling, decreasing non-cut time significantly. It’s also coupled with the HYBRID AUTO GEAR (AG) package to complete the suite of SMOOTH TECHNOLOGY solutions for DONE IN ONE® gear production. In addition, the INTEGREX i-200ST AG eliminates the need for multiple setups for better lead times and accuracy. The 5-axis capabilities allow it to process fully prismatic parts from solid blocks or castings, and round or sculptured parts with precision and flexibility. This makes the machining center work for applications such as aerospace, energy, and automotive components.

Key Features for Optimal Performance

The INTEGREX i-200ST AG delivers datum features, chamfers, edges, and more in a single setup to significantly enhance productivity. It also employs the SMOOTH Gear Cutting software to produce external and internal spur, helical, and spline-type gears. Its MX Hybrid Roller Guide System also mitigates vibration to prolong tool life and support higher load capacities. With a standard 36-tool magazine that can be expanded to 72 and 110 tools, the machine caters to extensive machining demands. It accommodates parts up to 25.9″ (658 mm) in diameter, offering broad versatility for the production of complex parts.

Master Complex Parts Manufacturing with Mazak

The INTEGREX i-200ST AG HYBRID stands at the forefront of Mazak’s 5-axis multi-tasking CNC and machining centers. With its advanced multi-tasking capabilities, this machine sets new benchmarks in the manufacturing industry.

Compare to other Mazak 5-Axis machines for sale