Description

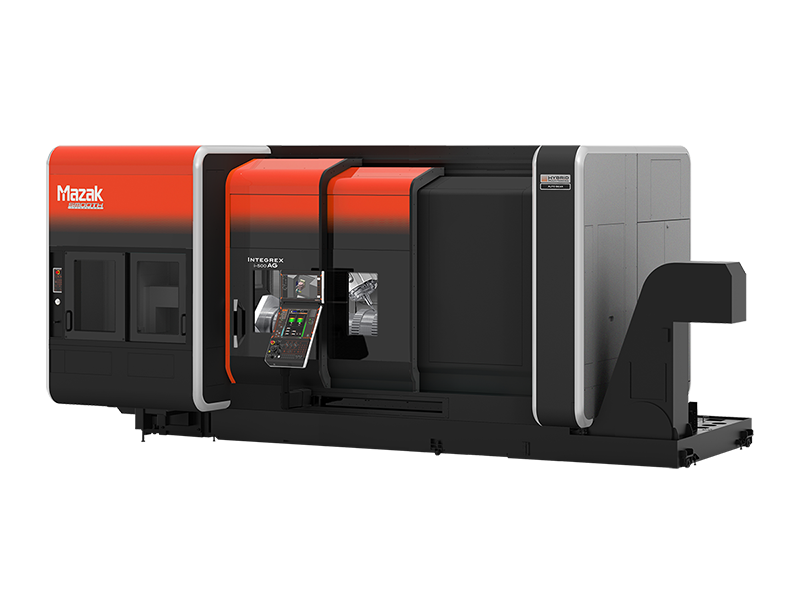

The INTEGREX i-500S AG Offers Unrivaled Precision and Efficiency in Gear Production

This machine features a secondary turning spindle (S) to ensure DONE IN ONE® machining. This feature streamlines the production process by minimizing the necessity for multiple setups. In addition, the integration of the HYBRID AUTO GEAR (AG) package encompasses the full spectrum of SMOOTH TECHNOLOGY solutions. This suite of gear manufacturing technology enables the machine to significantly cut down on lead times and enhance part accuracy. As a result, it’s a cornerstone of precision engineering with Mazak 5-Axis Multi-Tasking.

Advanced 5-Axis Capabilities for Complex Part Processing

With its advanced 5-axis capabilities, the INTEGREX i-500S AG effortlessly processes fully prismatic parts from solid blocks or castings—whether chucked or bar fed. This includes round parts or intricately sculptured aerospace components. The adaptability on this Mazak CNC machine enables it to create accurate and precise parts for demanding industries such as aerospace automotive, and contract manufacturing.

Highlighting INTEGREX i-500S AG’s Cutting-edge Features

This 5-axis machining center is designed to optimize efficiency and accuracy in machining operations. by incorporating the SMOOTH Gear Cutting software package, the INTEGREX i-500S AG offers comprehensive gear manufacturing solutions, including SMOOTH Gear Skiving, Hobbing, and Milling. As a result, it’s ideal for the production of external and internal spur, helical, and spline-type gears. In addition, the MX Hybrid Roller Guide System effectively dampens vibration to extend tool life and accommodate higher load capacities. These advanced features optimize workflows by reducing turnaround times, and elevating the overall output quality to position machine shops at the forefront of competitive manufacturing landscapes.

Compare to other Mazak 5-Axis machines for sale